Welcoming The World Of Cobots To Industries

The World Economic Forum in 2018 predicted that by the time 2022 comes around 75 million jobs will be displaced due to automation. They also predicted that 133 million jobs would also be created. All in all, automation will add 58 million posts worldwide. It is apparent that automation is not out to get the human workers, which is why it has become so evident on shop floors.

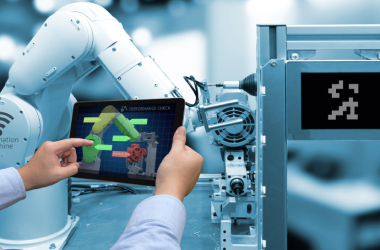

The collaboration between humans and robots is increasing so much that it augments the roles of people. They get more free time and therefore, are involved in activities that have a higher value. At the end of the day, cobots are leading better output, greater productivity, and higher efficiency.

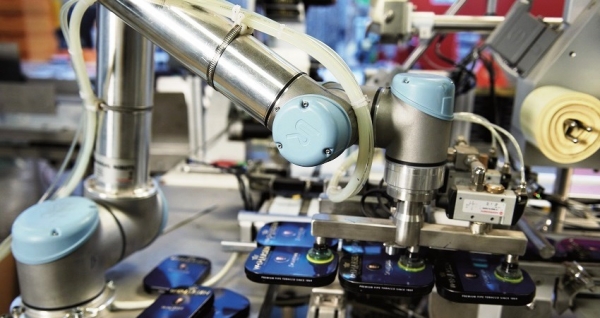

What are cobots? Collaborative robots capable of performing tasks alongside human workers are called Cobots. They can share the workspace with humans and interact with them without any danger. They are easily integrated into any current factory environment and interoperable, which has advanced their adoption in many sectors in the past few years. Check out here on the future of cobots.

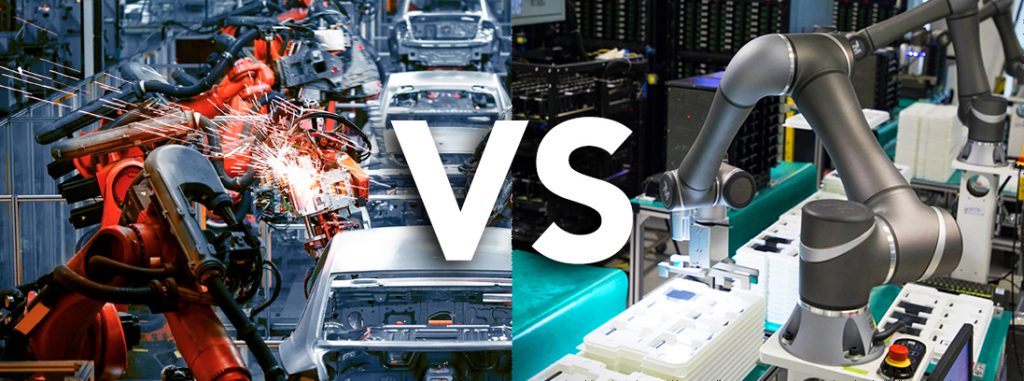

The Difference Between Cobots & Traditional Robots

The rise of cobots in industries arises from the features that differentiate them from conventional industrial robots. Just a few of these abilities and modifications are:

- We know that industrial robots have played a central role in many segments, but they are not 100% safe. Cobots, on the other hand, are automated machines that can be safely utilized alongside human beings.

- When compared with industrial robots, cobots are far more agile and responsive. It means cobots can meet the continually changing demands of manufacturing (and other industries).

- Industrial robots are mostly employed for repetitive tasks with linearity. The common ones are assembly and moving. But because they are heavy and not built to be intuitive, they pose a significant risk to human employees. Cobots are light and highly intuitive. They are made to stop mid-way if they sense a human approaching or obstacle.

- Because industrial robots are programmed offline, they rarely can respond to new stimuli in the middle of a new task which makes them constrained. Cobots come with force-torque sensors that make them power off the instant they sense the presence of a worker!

Cobots are highly intelligent. So much so, that they have reached the next era of industrial tech innovation. Called HRA or Human-Robot Augmentation, it involves programming a cobot to be the extension of a human employee. This would lead to increased sensitivity and greater precision in work. Better operations and the decreased risk of injury are not the only reasons Cobots are the future of all industries.

The Value Cobots Bring To Industries

Cobots offer a greater return on investment because:

- They amplify productivity to a great extent.

- They lower the cost in specific tasks and sectors.

- They do not get tired and make errors like human workers.

- They do not lose concentration and increase chances of injury like people.

Once programmed, cobots can safely and efficiently perform tedious, dull, or repetitive tasks ad nauseam. While all these are characteristics that paint a very bright future for industries, the most consequential value of cobots is somewhat different.

Collaborative robots don’t replace the workforce. They augment it. Every time a factory installs a cobot, they create complementary roles which need to be fulfilled by humans. Ultimately, they are helping humans build faster and more efficient production lines. Moreover, cobots are increasing job satisfaction levels.

No worker likes to perform the same function day in and day out for years, especially one that doesn’t require much brain power. When cobots take over such menial, strenuous, or repetitive operations, they give the engineer the time to pay attention to other higher functions. Ultimately, offering them satisfaction in their role.

The use of cobots in any industry is the opening of opportunities such as zero shortage of skilled workers and reduced manufacturing pressure. It is why they are, without a doubt, the future of all trades.